Behind the data-driven logic of AirREGI Handy’s Kitchen Monitor: Making way for more “Golden Experiences” at restaurants

Kitchen

Monitor

(only in Japanese), a new feature of AirREGI

Handy

(only in Japanese), is an order entry system that makes ordering,

cooking, and serving food easier and more time efficient. Operated on an

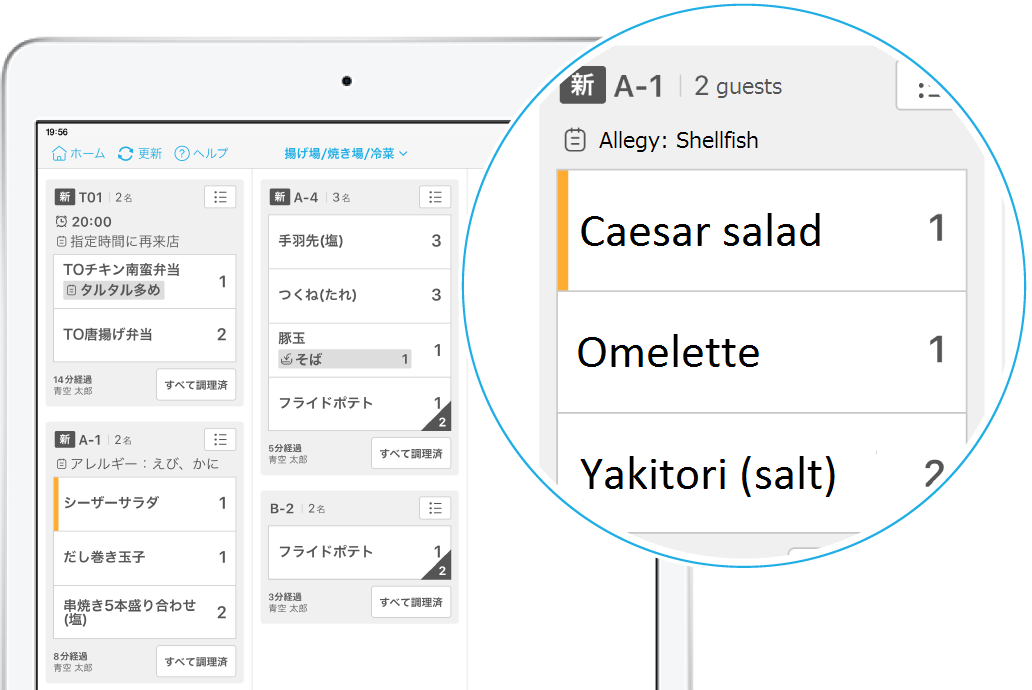

iPad, Kitchen Monitor automatically lists food orders based on their

time of submission and prepped time sequence, allowing kitchen staff to

see which orders are running late. It also helps to see the total number

of orders for one dish, which is useful when cooking in bulk. Dining

area staff can use the feature to check the status of the order and

where the food should be delivered in the restaurant. They can also see

the time elapsed since the order was placed, making it easier to notice

delays in food service. We interviewed Ryosuke Sudo, the developer of

this system, from Recruit Co., Ltd.

Kitchen Monitor allows users to see at a glance which tables are placing what orders. *This service is only provided in Japanese.

The top customer complaint is long wait times for food

“Recruit’s planning and development team members and I often talk about our ‘golden experiences’ at restaurants — experiences where we as customers received great customer service, and didn’t have to deal with long wait times for their food orders, or wait around for drinks to be served for the first toast. Drawing from these conversations, we began thinking about how to optimize the food ordering process to minimize delays," said Ryosuke.

When reviewing dissatisfied comments* of the izakaya (Japanese style pub) businesses, "slow service" tops the list. In order to understand and address service delays, many restaurants will spend money on expensive equipment and undercover surveys — a solution that isn’t as attainable for small and medium-sized establishments. Even so, many restaurants struggle to gauge which dishes are being served late, how late they arrive, and how often food is served late.

"Our team had an idea to establish a target time for completing a dish using two sets of time: the amount of time between taking an order to completing it, which was obtained from AirREGI Handy, and the estimated time of the actual cooking,” said Ryosuke. “With this target time, we wanted to calculate the optimal cooking order to prevent delays.”

*Customers’ comments were analyzed by text data mining, a method of analyzing text data that involves extracting and separating useful data consisting of ordinary sentences into words and phrases, and analyzing their frequency, correlation of co-occurrence, trend of occurrence, time series, etc.

Calculating the optimal cooking time and procedure using in-person field data

However, Ryosuke suspected more factors were at play, and knew that simply looking at the timing data wouldn’t tell the full story or solve the main problem. He decided to go to the actual restaurants to understand the processes that produced the data, which was not visible in the data alone.

"Observing the kitchens in person encouraged me to begin rethinking the data from the restaurant’s perspective. It was then that I was reminded of how it is important to handle data with an understanding of the restaurant industry and kitchens.”

“During our data analysis, questions kept popping up,” said Ryosuke. “Why was it that when the miso-pickled cucumbers were ordered at 6:09 p.m. and the cabbage salad was ordered at 6:18 p.m., the cabbage salad arrived first before the miso-pickled cucumbers? Or why was it that when the omelette was ordered, the timing of other dishes was affected?”

When Ryosuke observed the kitchen activity, he discovered several time management issues. He found that the chefs started with the easy-to-prepare cabbage salad, and that the omelette required more time and attention to cook as it was the restaurant’s signature dish, making it difficult to proceed to other dishes. Though this issue didn’t apply to all dishes, including skewered dishes such as yakitori, which are cooked one by one and placed together on a net grill as four or five skewers. Logistical factors such as how many people were working in the kitchen on a given day also impacted the number of delays. Through this on-site experience, Ryosuke was able to understand the actual situation at hand, and could then formulate an optimal cooking procedure by comparing the data with the actions and thought processes of the kitchen staff.

Following his investigation, Ryosuke derived an algorithmic method to calculate the optimal cooking time. At the participating restaurants, the normal cooking order and the optimized cooking order using Kitchen Monitor were verified every week for eight weeks, and the cooking delay rate and the rate of adopting the cooking order were compared. The results showed that the optimized cooking order led to a reduction in the number of cooking delays and a high rate of adopting the optimized cooking order, indicating that even experienced chefs trusted the Kitchen Monitor.

According to Ryosuke, "The results show that Kitchen Monitor was effective in reducing the number of cooking delays without changing the business operations of the restaurant. This made me very happy as an engineer.”

Improved operations in dining areas and kitchens

Restaurants using Kitchen Monitor have praised the feature for increasing kitchen oversight and productivity:

"Since introducing Kitchen Monitor, we can see at a glance which dishes are ordered and how often, and the total number of orders, which is really helpful. Orders for the same dish can be cooked together, leading to increased kitchen productivity.”

“We can now visualize the average cooking time for each dish, which we had only been able to approximate. We can also determine which steps should be taken in advance to prepare dishes that require longer cooking times, resulting in shorter cooking times once an order is placed.”

“On days when I am busy and need to stay in the dining area, I can monitor the cooking status of the kitchen from the dining area on my tablet, which makes it easier for me to operate and manage the entire restaurant.”

Ryosuke expressed his enthusiasm for the project. "With the enhancement of the current algorithm, restaurants can serve food at the same table all at once, and manage the status of food orders between tables. We look forward to improving Kitchen Monitor to create more golden experiences."

Ryosuke Sudo

Travel, Food & Beverage, Beauty, SaaS Data Group, Data Engineering Department, Data Engineering Unit, Product Development Management Office, Data Promotion Office, Product Management Division, Recruit Co., Ltd.

Ryosuke joined Recruit Lifestyle in 2018 after working in program development for an automobile manufacturer system. At Recruit Lifestyle, he has been involved in the data engineering, travel, and SaaS domains, and is currently in charge of planning and developing data-based policies. His hobbies include gaming and watching the NBA. Ryosuke enjoys watching NBA games every morning before going to work.